Admin BRL

Elite Explorer

- Joined

- February 15, 2024

- Messages

- 20

- Reaction score

- 14

- Location

- Brazil

- City, State

- Sao paulo , Brazil

- Year, Model & Trim Level

- 1993/94 XLT Explorer 4.0

Hello all!

Ford explorer 1st gen (91-94) is a unusual car here in Brazil. I could say it is rare... no parts, no junkyard cars to pick some parts, nothing. Only few explorers were sold here.

So, it means that whatever is needed to this car, must be done recovering the actual parts .

Then, let´s start with something small, but essential: the windshield water pump. Mine was clogged, stucked and corrroded.

- Empty both reservoirs, and remove the box from engine bay. Mine had two 8mm screws, each side of this box. Had to disconnect the windshield hose at the box, and disconnect the hose to radiator at the radiator neck.

- Once you have pulled out the plastic box, locate the pump. It will be at bottom, tucked in a hole down on that box.

- To keep this pump at it´s place, there´s one ring. Remove carefully this ring, because we need it at the end again . Be gentle, I mean don´t get it out using a wrech and a hammer... this one, at the pic, is broken .

- Once removed, just pull the pump , it will slide out. On this case, you can grab it with some plier by the connector edge.

The above images i get from one youtube video that I used to learn about this. Link to video: .

Now, the hands-on on this little guy:

- Pull the white part . It will slide out, that is the water propeller, it fits in the axle at one position only, mind it because at the end we will need put it back.

It should be like this :

- Now, we have to unlock the other part . There is 3 hatches, which we need to turn that out. Take a good look, because we will need to bend it back at the end.

- Once it is bended outside, you can slide out the connector with the rotor.

- And now begins the cleaning. In my pump, i had a lot of rust and dust. Is essencial to clean it all , make it mint. I have used a CAR-80 degreaser/decarbonizer, and some sandpapers.

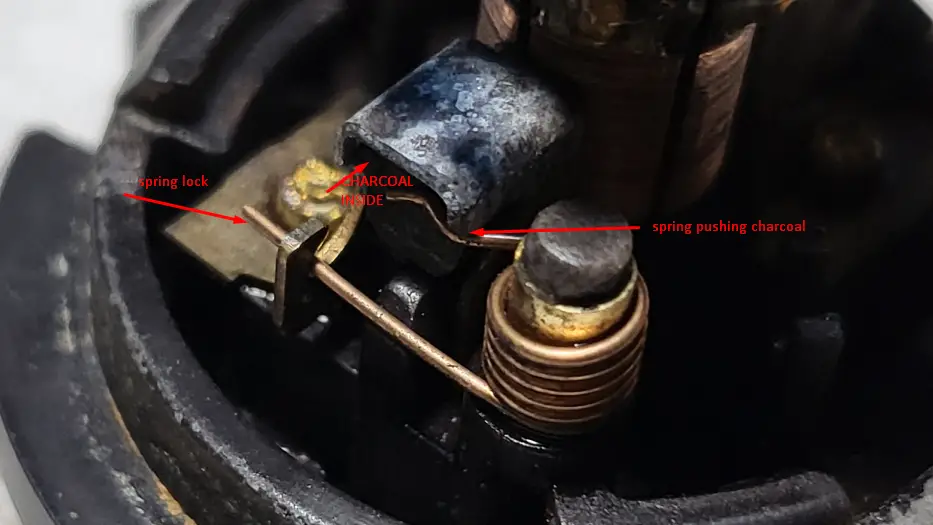

- As this is a eletric engine, it have bushigs, like any one other eletric tool.. here a detail of it:

- unlock the spring, and mind the spring position: the twisted side is up. Now remove the spring, and the charcoal must be loose. do this both sides.

- With these loose, remove the axle. just pull it.

Details:

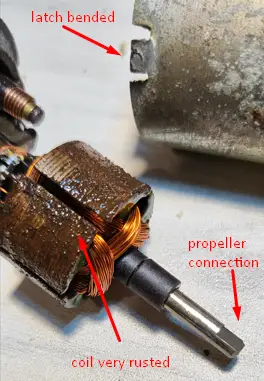

- Do a visual inspection at these wires. Mine had some toasted, but not much. if you have wires burned or snapped at this point, probably it will not work, or will work with low power.

- Now clean it all. All parts. I washed with CAR-80 and a toothbrush, washed with water, washed with dish soap and scrubbed again with toothbrush, washed with water again. Once it get more clean, begin with sandpaper.

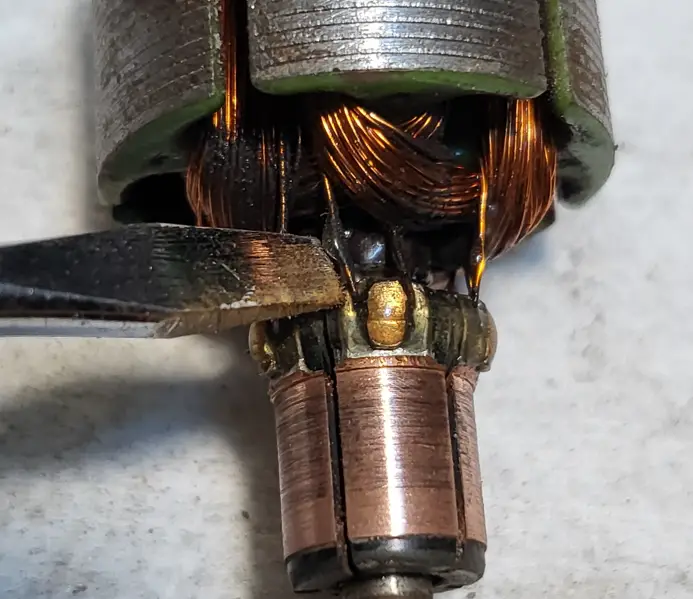

- Using sandpaper, get rid of all rust, and any bump.. get it very smooth. keep in mind it will rotate, and can´t grind .

-Its clean and sanded. Some spots still exist, but cant even be feeled .. it is smooth. This part indicated at the picture above, must be sanded carefully, just to remove some dirt. This is where the electrical contact are done.

- This case must be cleaned, and this bulge at center is a magnet. don´t sand it. But it must be clear , smooth and with no parts and bulges. that rotor will rotate (pun intended) inside it, and can´t touch the magnet. sand the outside, scrub inside, get it very clean and with no loose parts .

- I put some grease in the axle connections: each axle side seats at some bushing. so, i lubricated it with grease. In my case, i used some alti-seize grease, but I think any grease could be used. Not a lubricant spray, but a grease itself.

Now the easy part, mount it all and it´s done! haha

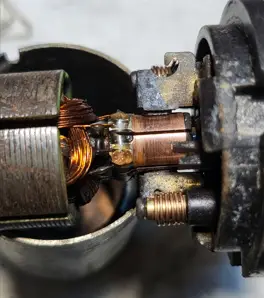

Here with axle mounted, and mounting the springs.

springs done, now mount it into the shell.

This is what looks like when done .. now let´s put it back. I tested it outside, just connected the pump to the car and tried , it works fine now.

- Clean very well the housing at reservoir.

- In my case, after the pump placed back , was leaking. I removed it, and applied some teflon tape at the sealant rubber, and shoved it inside again. Watch out to don´t get tape in front , at the propeller... just around the rubber.

- once fitted, and pushed all way in, assemble that lock (the one first we removed, with teeths) and push that lock firmly, it must guarantee the pump will not slide back .

- Put some water in, and try to use it.... mine now is working perfect.

Hope it helps somebody

- ADM_BRL

Ford explorer 1st gen (91-94) is a unusual car here in Brazil. I could say it is rare... no parts, no junkyard cars to pick some parts, nothing. Only few explorers were sold here.

So, it means that whatever is needed to this car, must be done recovering the actual parts .

Then, let´s start with something small, but essential: the windshield water pump. Mine was clogged, stucked and corrroded.

- Empty both reservoirs, and remove the box from engine bay. Mine had two 8mm screws, each side of this box. Had to disconnect the windshield hose at the box, and disconnect the hose to radiator at the radiator neck.

- Once you have pulled out the plastic box, locate the pump. It will be at bottom, tucked in a hole down on that box.

- To keep this pump at it´s place, there´s one ring. Remove carefully this ring, because we need it at the end again . Be gentle, I mean don´t get it out using a wrech and a hammer... this one, at the pic, is broken .

- Once removed, just pull the pump , it will slide out. On this case, you can grab it with some plier by the connector edge.

The above images i get from one youtube video that I used to learn about this. Link to video: .

Now, the hands-on on this little guy:

- Pull the white part . It will slide out, that is the water propeller, it fits in the axle at one position only, mind it because at the end we will need put it back.

It should be like this :

- Now, we have to unlock the other part . There is 3 hatches, which we need to turn that out. Take a good look, because we will need to bend it back at the end.

- Once it is bended outside, you can slide out the connector with the rotor.

- And now begins the cleaning. In my pump, i had a lot of rust and dust. Is essencial to clean it all , make it mint. I have used a CAR-80 degreaser/decarbonizer, and some sandpapers.

- As this is a eletric engine, it have bushigs, like any one other eletric tool.. here a detail of it:

- unlock the spring, and mind the spring position: the twisted side is up. Now remove the spring, and the charcoal must be loose. do this both sides.

- With these loose, remove the axle. just pull it.

Details:

- Do a visual inspection at these wires. Mine had some toasted, but not much. if you have wires burned or snapped at this point, probably it will not work, or will work with low power.

- Now clean it all. All parts. I washed with CAR-80 and a toothbrush, washed with water, washed with dish soap and scrubbed again with toothbrush, washed with water again. Once it get more clean, begin with sandpaper.

- Using sandpaper, get rid of all rust, and any bump.. get it very smooth. keep in mind it will rotate, and can´t grind .

-Its clean and sanded. Some spots still exist, but cant even be feeled .. it is smooth. This part indicated at the picture above, must be sanded carefully, just to remove some dirt. This is where the electrical contact are done.

- This case must be cleaned, and this bulge at center is a magnet. don´t sand it. But it must be clear , smooth and with no parts and bulges. that rotor will rotate (pun intended) inside it, and can´t touch the magnet. sand the outside, scrub inside, get it very clean and with no loose parts .

- I put some grease in the axle connections: each axle side seats at some bushing. so, i lubricated it with grease. In my case, i used some alti-seize grease, but I think any grease could be used. Not a lubricant spray, but a grease itself.

Now the easy part, mount it all and it´s done! haha

Here with axle mounted, and mounting the springs.

springs done, now mount it into the shell.

This is what looks like when done .. now let´s put it back. I tested it outside, just connected the pump to the car and tried , it works fine now.

- Clean very well the housing at reservoir.

- In my case, after the pump placed back , was leaking. I removed it, and applied some teflon tape at the sealant rubber, and shoved it inside again. Watch out to don´t get tape in front , at the propeller... just around the rubber.

- once fitted, and pushed all way in, assemble that lock (the one first we removed, with teeths) and push that lock firmly, it must guarantee the pump will not slide back .

- Put some water in, and try to use it.... mine now is working perfect.

Hope it helps somebody

- ADM_BRL